-

LQ-900 Carry Bag Maker

Plastic bag making machine is special design for silting and sealing, 1 pcs big jambo roll slit and cut into 2 small rolls in high speed production. 2 independent computers control design and driven by 5.5KW servo motor. Carry bag maker is also Suitable for producing disposable plastic T-shirt bags.

Termsof Payment

30% deposit by T/T when confirming the order, 70% balance by T/T before shipping.Or irrevocable L/C at sight.

Warranty: 12 months after B/L date.

It is ideal equipment of plastic industry. More convenient and easy to do adjustment, save labours and cost to support our customers do more effierency. -

LQ-450X2 Biodegradable plastic bag making machine

This machine is two lines heat sealing and heat cutting design, which are suit for printed bag and non-printed bag production. The material of bag which machine can make is HDPE, LDPE and recycle materials and films with filers and biodegradable films.

Terms of Payment

30% deposit by T/T when confirming the order.

70% balance by T/T before shipping.

Or irrevocable L/C at sight.

Warranty: 12 months after B/L date. -

LQ-700 Eco Friendly Plastic Bag Making Machine Factory

LQ-700 machine is bottom sealing perforation bag machine. Machine has two times triangle V-fold units, and film can be fold one time or two times. The best thing is that the position of triangle fold can be adjusted. Machine design for sealing and perforating first, then fold and rewinding in the last. Double times V-folds will make film smaller and bottom sealing.

Terms of Payment

30% deposit by T/T when confirming the order.

70% balance by T/T before shipping.

Or irrevocable L/C at sight.

Warranty: 12 months after B/L date. -

LQ-300X2 Biodegradable Plastic Bag Making Machine Suppliers

This machine is heat sealing and perforation for bag rewinding, which are suit for printing and non-printing bag making. The material of bag is biodegradable film, LDPE, HDPE and recycle materials.

-

LQ-450X2 Plastic Bag On Roll Making Machine Made In China

LQ–450X2 is deigned for bag-on-roll bags with paper or PVC core production. It’s automatic film-break and core-change functions help bag suppliers to improve bag making capacity and to reduce energy and man power at the most extent. Its double servo motors control system makes producing more stable. It is the best choice for making bottom sealing printed bags and blank bags.

Terms of Payment

30% deposit by T/T when confirming the order.

70% balance by T/T before shipping.

Or irrevocable L/C at sight.

Warranty: 12 months after B/L date. -

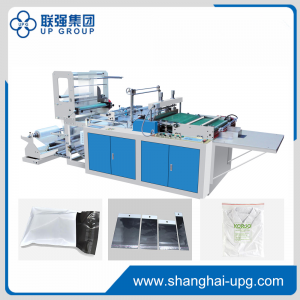

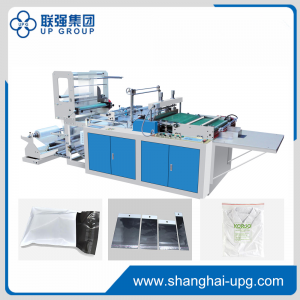

LQ-600C Three-side Sealing Automatic Bag Making Machine Suppliers

Terms of Payment

30% deposit by T/T when confirming the order, 70% balance by T/T before shipping. Or irrevocable L/C at sight.

Warranty: 12 months after B/L date.

It is ideal equipment of plastic industry. More convenient and easy to do adjustment, save labours and cost to support our customers do more effierency. -

LQ-BQ Series Side Seal Heat Plastic Cutting Bag Making Machine Factory

The side seal bags is different from bottom seal bags and star seal bags, it is seald at the length, while opening at the width. So it is possible to make self-sticking bags, draw-string bags.

Terms of Payment

30% deposit by T/T when confirming the order, 70% balance by T/T before shipping. Or irrevocable L/C at sight.

Warranty: 12 months after B/L date.

It is ideal equipment of plastic industry. More convenient and easy to do adjustment, save labours and cost to support our customers do more effierency.