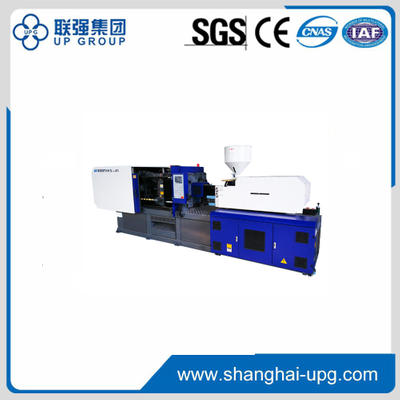

China Wholesale Plastic Blow Moulding Machine Suppliers – Injection Molding Machine – UP Group Detail:

Performance

- The system pressure and flow of the servo injection molding machine are double closed-loop, and the hydraulic system supplies oil according to the actual flow and pressure, which overcomes the high energy consumption caused by the high pressure overflow of the common quantitative pump system. The motor works according to the set speed in the high flow stage such as pre molding, mold closing and glue injection, and reduces the motor speed in the low flow stage such as pressure maintaining and cooling. The oil pump motor actually can Consumption has been reduced by 35% – 75%.

- The advantages of servo injection molding machine, such as energy saving, environmental protection, high repetition accuracy, reliability and durability, have been favored by the market and praised by users.

Specification

| Model

|

HHF68X-J5 |

HHF110X-J5 |

HHF130X-J5 |

HHF170X-J5 |

HHF230X-J5 |

|||||||||||

|

A |

B |

C |

A |

B |

C |

A |

B |

C |

A |

B |

C |

A |

B |

C |

||

| INJECTION UNIT | ||||||||||||||||

| Screw Diameter | mm |

28 |

30 |

32 |

35 |

38 |

42 |

38 |

42 |

45 |

40 |

45 |

48 |

45 |

50 |

55 |

| Screw L/D Ratio | L/d | 24.6 |

23 |

21.6 |

24.6 |

24.3 |

22 |

24.3 |

22 |

20.5 |

24.8 |

22 |

20.6 |

26.6 |

23.96 |

21.8 |

| Shot size | cm3 |

86 |

99 |

113 |

168 |

198 |

241 |

215 |

263 |

302 |

284 |

360 |

410 |

397 |

490 |

593 |

| Injection Weight (PS) | g |

78 |

56 |

103 |

153 |

180 |

219 |

196 |

239 |

275 |

258 |

328 |

373 |

361 |

446 |

540 |

| Injection Rate | g/s |

49 |

56 |

63 |

95 |

122 |

136 |

122 |

150 |

172 |

96 |

122 |

138 |

103 |

128 |

155 |

| Plasticizing Capacity | g/s |

6.3 |

8.4 |

10.3 |

11 |

12 |

15 |

11 |

14 |

17 |

16.2 |

20 |

21 |

19 |

24 |

29 |

| Injection Pressure | Mpa |

219 |

191 |

168 |

219 |

186 |

152 |

176 |

145 |

126 |

225 |

178 |

156 |

210 |

170 |

140 |

| Screw Speed | rpm |

0-220 |

0-220 |

0-220 |

0-185 |

0-185 |

||||||||||

| CLAMPING UNIT | ||||||||||||||||

| Clamp Tonnage | KN |

680 |

1100 |

1300 |

1700 |

2300 |

||||||||||

| Toggle Stroke | mm |

300 |

320 |

360 |

430 |

490 |

||||||||||

| Space Bet. Tie-bars | mm |

310×310 |

370×370 |

430×415(415×415) |

480×480(470×470) |

532×532 |

||||||||||

| Max.Mold height | mm |

330 |

380 |

440 |

510 |

550 |

||||||||||

| Min.Mold height | mm |

120 |

140 |

140 |

170 |

200 |

||||||||||

| Ejector Stroke | mm |

80 |

100 |

120 |

140 |

140 |

||||||||||

| Ejector Tonnage | Kn |

38 |

45 |

45 |

45 |

70 |

||||||||||

| Ejector Number | PC |

5 |

5 |

5 |

5 |

9 |

||||||||||

| OTHERS | ||||||||||||||||

| Max.Pump Pressure | Mpa |

16 |

16 |

16 |

16 |

16 |

||||||||||

| Pump Motor Power | Kw |

7.5 |

11 |

13 |

15 |

18.5 |

||||||||||

| Heater Power | Kw |

6.15 |

9.8 |

9.8 |

11 |

16.9 |

||||||||||

| Machine Dimension | m |

3.4×1.1×1.5 |

4.2×1.15×1.83 |

4.5×1.25×1.86 | 5.1×1.35×2.1 | 5.5×1.42×2.16 | ||||||||||

| Machine Weight | T |

2.6 |

3.4 |

3.7 |

5.2 |

7 |

||||||||||

| Oil Tank Cap | L |

140 |

180 |

210 |

240 |

340 |

||||||||||

Product detail pictures:

Related Product Guide:

It is a good way to enhance our products and solutions and repair. Our mission will be to build creative solutions to consumers with a great experience for China Wholesale Plastic Blow Moulding Machine Suppliers – Injection Molding Machine – UP Group, The product will supply to all over the world, such as: Portland, Zambia, Croatia, With the development and enlargement of mass clients abroad, now we've set up cooperative relationships with many major brands. We've our own factory and also have many reliable and well-cooperated factories in the field. Adhering to the "quality first, customer first, We are provideing high-quality, low-cost items and first-class service to customers. We sincerely hope to establish business relationship with customers from all over the world on the basis of quality, mutually benefit. We welcome OEM projects and designs.

The sales manager is very patient, we communicated about three days before we decided to cooperate, finally, we are very satisfied with this cooperation!