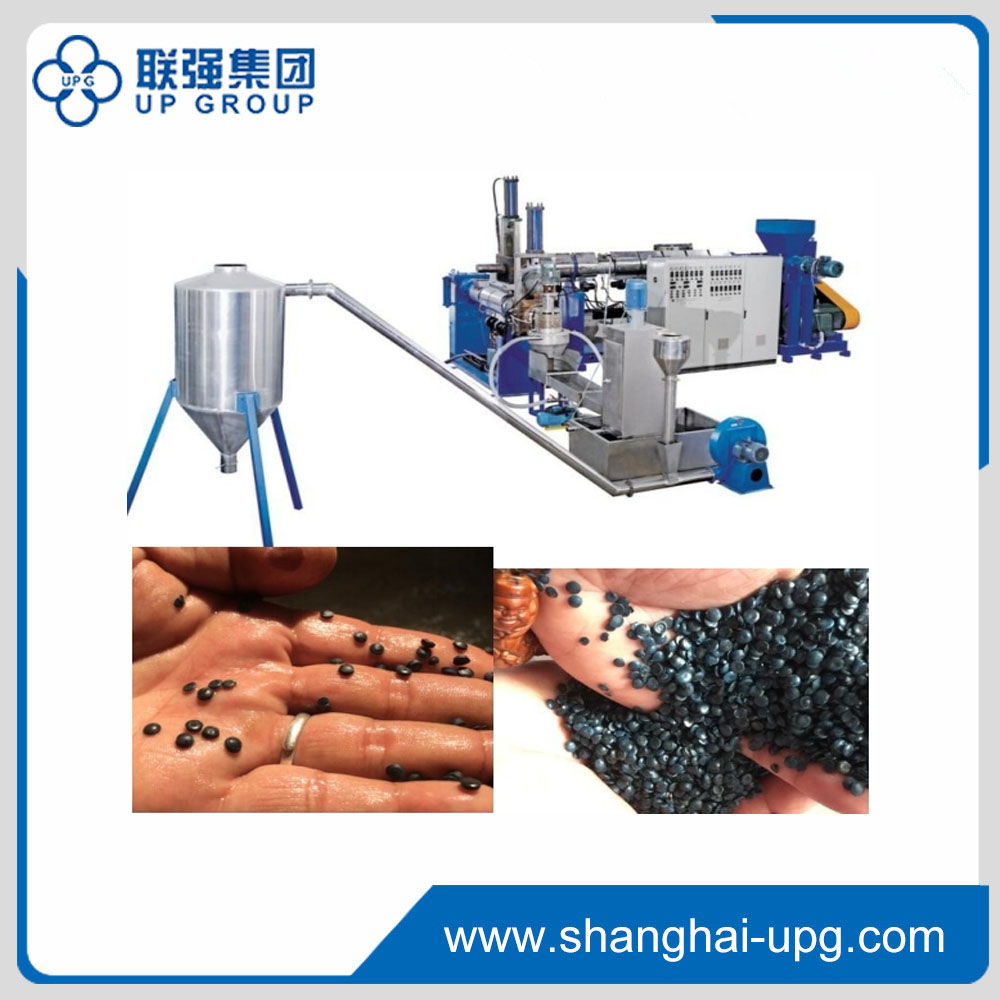

China Wholesale Plastic Granulating Extruder Machine Manufacturers – LQ150-200 PE Film Double-stage Pelletizing Line – UP Group Detail:

Detail Parameter

Detail parameter:

Belt conveyor

| Effective width | 600mm |

| Motor power | 1.5KW |

Agglomeration room

| Motor power | 45KW |

| Total Volume | 200L |

| Effective volume | 150L |

| Rotary blade | 9 |

| Fixed blade | 12 |

| Blades rotation speed | 900RPM |

LQ-SJ85/28 Extruder

| Driving motor | 55 KW, AC motor(SIMENS China) |

| Screw | |

| Diameter of screw | 85mm |

| L/D | 28/1 |

| Material of screw | 38CrMoAl |

| Surface treatment | Nitriding processing |

| Barrel | |

| Inner processing | nitride |

| Heating power | 55KW |

| Cooling air fans | 0.37KWx5 sets |

| Gear box | Special hard gear reducer |

| Venting system | |

| Vacuum pump | 2.2KWx1set |

| Electric cabinet | |

| Speed regulator | ABB inverter |

| Contactor | SIEMENS |

| Relay | Omron |

| Temperature controller | Omron |

Hydraulic screen changer

| Changing screen time≤2 sec | |

| Screen diameter | 200mm |

| Motor power | 1.5 KW |

LQ-SJ85/10 Extruder

| Driving motor | 22 KW, AC motor(SIMENS China) |

| Screw | |

| Diameter of screw | 85mm |

| L/D | 10/1 |

| Material of screw | 38CrMoAl |

| Surface treatment | Nitriding processing |

| Barrel | |

| Heating power | 22KW |

| Cooling air fans | 0.72KW |

| Gear box | Special hard gear reducer |

| Electric cabinet | |

| Speed regulator | ABB inverter |

| Contactor | SIEMENS |

| Relay | Omron |

| Temperature controller | Omron |

Hydraulic screen changer

Motor power: 2.2 KW

Water-ring cutter

| Motor power | 1.1 KW |

| Water pump power | 3 KW |

| Blade | 2-4 pcs |

| Part contact with water is made of stainless steel (S.S.) | |

Conveying channel & water tank

Basic material of channel & tank body: stainless steel

Centrifugal dryer

Motor Power: 3KW

Packing system

| Loading power | |

| Motor power | 3 KW |

| Conveying pipeline | S.S |

| Silo | |

| Material of storage silo | S.S |

| Silo frame | Carbon steel |

| Volume of silo | 500L |

Electric Controller

| Electronic control components(including circuit breakers, AC contactor, button, indicator light.) | |

| Temperature controller | OMRON |

| Contractor | SIEMENS |

| Other | DELIXI |

Product detail pictures:

Related Product Guide:

We have probably the most state-of-the-art output equipment, experienced and qualified engineers and workers, recognized good quality manage systems plus a friendly skilled income workforce pre/after-sales support for China Wholesale Plastic Granulating Extruder Machine Manufacturers – LQ150-200 PE Film Double-stage Pelletizing Line – UP Group, The product will supply to all over the world, such as: Singapore, Turin, Brasilia, Based on products with high quality, competitive price, and our full range service, we have accumulated professional strength and experience, and we have built up a very good reputation in the field. Along with the continuous development, we commit ourselves not only to the Chinese domestic business but also the international market. May you moved by our high quality products and passionate service. Let's open a new chapter of mutual benefit and double win.

The quality of the products is very good, especially in the details, can be seen that the company work actively to satisfy customer's interest, a nice supplier.