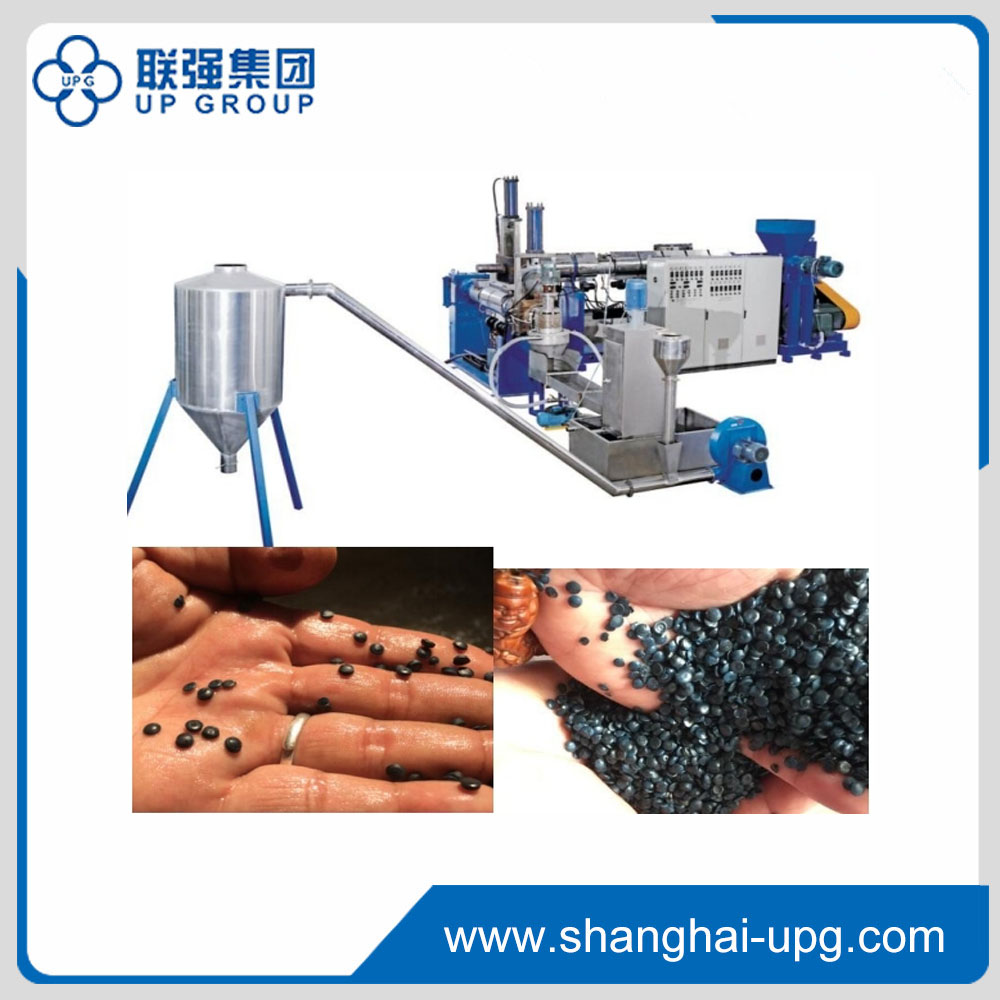

China Wholesale thermoformer Suppliers – LQ250-300PE Film Double-Stage Pelletizing Line – UP Group Detail:

Detail Parameter

Belt conveyor

| Effective width | 600mm |

| Motor power | 1.5KW |

Agglomeration room

| Motor power | 45KW |

| Total Volume | 200L |

| Effective volume | 150L |

| Rotary blade | 9 |

| Fixed blade | 12 |

| Blades rotation speed | 900RPM |

LQ-SJ85/28 Extruder

| Driving motor | 55 KW, AC motor(SIMENS China) |

| Screw | |

| Diameter of screw | 85mm |

| L/D | 28/1 |

| Material of screw | 38CrMoAl |

| Surface treatment | Nitriding processing |

| Barrel | |

| Inner processing | nitride |

| Heating power | 55KW |

| Cooling air fans | 0.37KWx5 sets |

| Gear box | Special hard gear reducer |

| Venting system | |

| Vacuum pump | 2.2KWx1set |

| Electric cabinet | |

| Speed regulator | ABB inverter |

| Contactor | SIEMENS |

| Relay | Omron |

| Temperature controller | Omron |

Hydraulic screen changer

| Changing screen time≤2 sec | |

| Screen diameter | 200mm |

| Motor power | 1.5 KW |

LQ-SJ85/10 Extruder

| Driving motor | 22 KW, AC motor(SIMENS China) |

| Screw | |

| Diameter of screw | 85mm |

| L/D | 10/1 |

| Material of screw | 38CrMoAl |

| Surface treatment | Nitriding processing |

| Barrel | |

| Heating power | 22KW |

| Cooling air fans | 0.72KW |

| Gear box | Special hard gear reducer |

| Electric cabinet | |

| Speed regulator | ABB inverter |

| Contactor | SIEMENS |

| Relay | Omron |

| Temperature controller | Omron |

Hydraulic screen changer

Motor power: 2.2 KW

Water-ring cutter

| Motor power | 1.1 KW |

| Water pump power | 3 KW |

| Blade | 2-4 pcs |

| Part contact with water is made of stainless steel (S.S.) | |

Conveying channel & water tank

Basic material of channel & tank body: stainless steel

Centrifugal dryer

Motor Power: 3KW

Packing system

| Loading power | |

| Motor power | 3 KW |

| Conveying pipeline | S.S |

| Silo | |

| Material of storage silo | S.S |

| Silo frame | Carbon steel |

| Volume of silo | 500L |

Electric Controller

| Electronic control components(including circuit breakers, AC contactor, button, indicator light.) | |

| Temperature controller | OMRON |

| Contractor | SIEMENS |

| Other | DELIXI |

Product detail pictures:

Related Product Guide:

To create extra value for customers is our enterprise philosophy; buyer growing is our working chase for China Wholesale thermoformer Suppliers – LQ250-300PE Film Double-Stage Pelletizing Line – UP Group, The product will supply to all over the world, such as: Greenland, Sweden, Myanmar, We have a strict and complete quality control system, which ensures that each product can meet quality requirements of customers. Besides, all of our products have been strictly inspected before shipment.

The product manager is a very hot and professional person, we have a pleasant conversation, and finally we reached a consensus agreement.

-

China Wholesale vacuum forming molding machine ...

-

China Wholesale Recycling granulation line Fact...

-

China Wholesale Hydraulic Plastic Baler Press M...

-

China Wholesale Hologram Printer Machine Factor...

-

China Wholesale Plastic Injection Moulding Manu...

-

China Wholesale Plastic Film Gravure Printing M...