-

LQ-TM-51/62 Full Automatic Thermoforming Machine manufacturer

Servo driven platen for smooth and energy efficient movement

Memory storage system

Optional working modes

Intelligent diagnostic analysis

Quick mould air baffle change

In-mould cutting ensuring consistent and accurate trim

Low energy consumption, high utilization

Robot with 180 degree rotation and dislocation palletizing -

LQ-450X2 Plastic Bag On Roll Making Machine Made In China

LQ–450X2 is deigned for bag-on-roll bags with paper or PVC core production. It’s automatic film-break and core-change functions help bag suppliers to improve bag making capacity and to reduce energy and man power at the most extent. Its double servo motors control system makes producing more stable. It is the best choice for making bottom sealing printed bags and blank bags.

Terms of Payment

30% deposit by T/T when confirming the order.

70% balance by T/T before shipping.

Or irrevocable L/C at sight.

Warranty: 12 months after B/L date. -

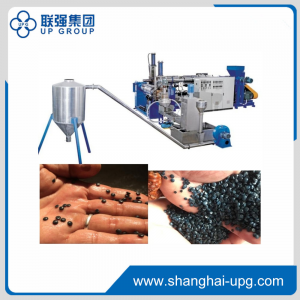

LQ250-300PE Film Double-Stage Pelletizing Line

Termsof Payment

30% deposit by T/T when confirming the order, 70% balance by T/T before shipping.Or irrevocable L/C at sight.

Installation and Training

The price includes the fee of installation, Training and interpreter, However, the relative cost such as international return air tickets between China and Buyer’s country, local transportation, accommodation (3 star hotel), and the pocket money per person for engineers and interpreter will be born by buyer. Or, the customer can find capable interpreter in local. If during Covid19, will do online or video support by whatsapp or wechat software.

Warranty: 12 months after B/L date.

It is ideal equipment of plastic industry. More convenient and easy to do adjustment, save labours and cost to support our customers do more effierency. -

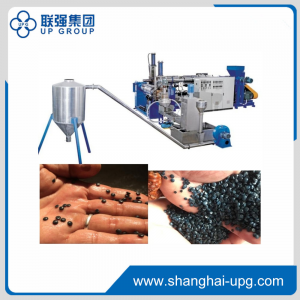

LQ-150/200 china fully automatic PE film plastic recycling machine manufacturers

Terms of Payment

30% deposit by T/T when confirming the order, 70% balance by T/T before shipping.Or irrevocable L/C at sight.

Warranty: 12 months after B/L date.

It is ideal equipment of plastic industry. More convenient and easy to do adjustment, save labours and cost to support our customers do more effierency. -

LQ TM-3021 Plastic Positive And Negative Thermoforming Machine

This flly automatic plastic thermoforming machine is a combination of mechanical, electrical and pneumatic components, and the whole system is contrlled by a micro PLC, which can be operated in man-interface.

It combines the material feeding, heating, forming, cutting and stacking into one process. It’s available for BOPS, PS, APET, PVC, PLA plastic sheet roll forming into various of lids, dishes, trays, clamshells and other products, such as lunch box lids, sushi lids, paper bowl lids, aluminum foil lids, moon cake trays,pastry trays, food trays, supermarket trays, oral liquid trays,medicine injection trays.Termsof Payment

30% deposit by T/T when confirming the order, 70% balance by T/T before shipping.Or irrevocable L/C at sight.Installation and Training

The price includes the fee of installation, Training and interpreter, However, the relative cost such as international return air tickets between China and Buyer’s country, local transportation, accommodation (3 star hotel), and the pocket money per person for engineers and interpreter will be born by buyer. Or, the customer can find capable interpreter in local. If during Covid19, will do online or video support by whatsapp or wechat software.Warranty: 12 months after B/L date.

It is ideal equipment of plastic industry. More convenient and easy to do adjustment, save labours and cost to support our customers do more effierency.

-

LQ TM-54/76 Full Automatic Thermoforming Machine

This flly automatic plastic thermoforming machine is a combination of mechanical, electrical and pneumatic components, and the whole system is contrlled by a micro PLC, which can be operated in man-interface.

It combines the material feeding, heating, forming, cutting and stacking into one process. It’s available for BOPS, PS, APET, PVC, PLA plastic sheet roll forming into various of lids, dishes, trays, clamshells and other products, such as lunch box lids, sushi lids, paper bowl lids, aluminum foil lids, moon cake trays, pastry trays, food trays, supermarket trays, oral liquid trays, medicine injection trays.

Termsof Payment

30% deposit by T/T when confirming the order, 70% balance by T/T before shipping.Or irrevocable L/C at sight.

Installation and Training

The price includes the fee of installation, Training and interpreter, However,the relative cost such as international return air tickets between China and Buyer’s country, local transportation, accommodation (3 star hotel), and the pocket money per person for engineers and interpreter will be born by buyer. Or, the customer can find capable interpreter in local. If during Covid19, will do online or video support by whatsapp or wechat software.

Warranty: 12 months after B/L date.

It is ideal equipment of plastic industry. More convenient and easy to do adjustment, save labours and cost to support our customers do more effierency. -

LQMG Series Plastic Crusher factory

All the rotor box crushing hopper of LQMG series have been redesigned to increase the crushing yield of hollow materials, such as plastic bottles and other blow modling products, and improve the crushing effect.

Termsof Payment

30% deposit by T/T when confirming the order, 70% balance by T/T before shipping.Or irrevocable L/C at sight.Warranty:12 months after B/L date.It is ideal equipment of plastic industry. More convenient and easy to do adjustment, save labours and cost to support our customers do more effierency.

-

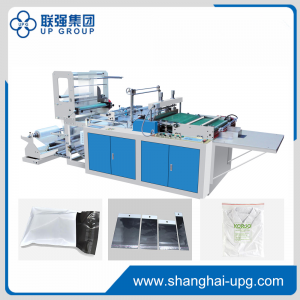

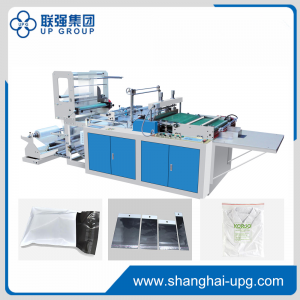

LQ-600C Three-side Sealing Automatic Bag Making Machine Suppliers

Terms of Payment

30% deposit by T/T when confirming the order, 70% balance by T/T before shipping. Or irrevocable L/C at sight.

Warranty: 12 months after B/L date.

It is ideal equipment of plastic industry. More convenient and easy to do adjustment, save labours and cost to support our customers do more effierency. -

LQ-BQ Series Side Seal Heat Plastic Cutting Bag Making Machine Factory

The side seal bags is different from bottom seal bags and star seal bags, it is seald at the length, while opening at the width. So it is possible to make self-sticking bags, draw-string bags.

Terms of Payment

30% deposit by T/T when confirming the order, 70% balance by T/T before shipping. Or irrevocable L/C at sight.

Warranty: 12 months after B/L date.

It is ideal equipment of plastic industry. More convenient and easy to do adjustment, save labours and cost to support our customers do more effierency. -

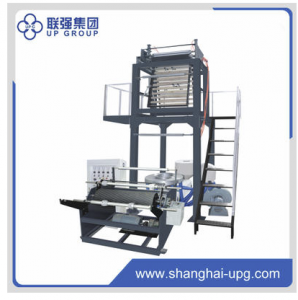

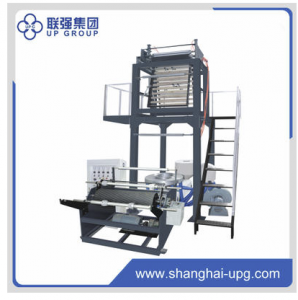

LQ A Series Single Layer Film Blowing Machine Wholesale

Blowing Film Machine extruder, cylinder and screw rods are made of quality alloy steel that have been nitrized and processed in a precision way. Hence it is sound in hardness, durable in corrosion resistance. The specially-designed screw is of sound quality in plasticizing, which helps increase the production capacity. Blowing Film Machine is applied to blowing the plastic films like low density polytene (LDPE), high density polytene(HDPE) and linear low density polytene (LLDPE). Blowing Film Machine is widely applied to producing the packing bags for foodstuff, clothing, rubbish bag and vest ones.

Termsof Payment:

30% deposit by T/T when confirming the order, 70% balance by T/T before shipping.Or irrevocable L/C at sight.

Installation and Training

The price includes the fee of installation, Training and interpreter, However, the relative cost such as international return air tickets between China and Buyer’s country, local transportation, accommodation (3 star hotel), and the pocket money per person for engineers and interpreter will be born by buyer. Or, the customer can find capable interpreter in local. If during Covid19, will do online or video support by whatsapp or wechat software.

Warranty: 12 months after B/L date.

It is ideal equipment of plastic industry. More convenient and easy to do adjustment, save labours and cost to support our customers do more effierency. -

LQ5L-1800 Five-layer co-extrusion film blowing machine manufacturer

The machine is used to produce five layers plastic film, die head type: A+B+C+D+E. The five-layer co extrusion film blowing machine produced by our company adopts advanced technologies such as a new high-efficiency and low energy consumption extrusion unit, IBC film bubble internal cooling system, ± 360 ° horizontal upward traction rotation system, ultrasonic automatic deviation correction device, fully automatic winding and film tension control, and computer screen automatic control system. Compared with similar equipment, it has the advantages of higher yield, good product plasticization, low energy consumption, and easy operation. The traction technology has reached a leading level in the domestic film blowing machine field, with a maximum output of 300kg/h for the SG-3L1500 model and 220-250kg/h for the SG-3L1200 model

Termsof Payment

30% deposit by T/T when confirming the order, 70% balance by T/T before shipping.Or irrevocable L/C at sight.

Installation and Training

The price includes the fee of installation, Training and interpreter, However, the relative cost such as international return air tickets between China and Buyer’s country, local transportation, accommodation (3 star hotel), and the pocket money per person for engineers and interpreter will be born by buyer. Or, the customer can find capable interpreter in local. If during Covid19, will do online or video support by whatsapp or wechat software.

Warranty: 12 months after B/L date.

It is ideal equipment of plastic industry. More convenient and easy to do adjustment, save labours and cost to support our customers do more effierency. -

LQ-CZ/1300 High Speed Slitting Machine manufacturers

High Speed Slitting Machine

Termsof Payment:

30% deposit by T/T when confirming the order,70% balance by T/T before shipping.Or irrevocable L/C at sight

Warranty:12 months after B/L date

It is ideal equipment of plastic industry. More convenient and easy to do adjustment, save labours and cost to support our customers do more effierency.