Product Description

Features:

1. Adopt Electro-Hydraulic Hybrid Servo System Can save 40% power than usual.

2. Apply the double vertical pole and single horizontal beam to make enough rotation space, longer bottles, make the mold installation easy and simple.

3. The injection mold adopt the double assistant cylinder open-close mold, ensure the stable and quick moving. The clamping force is three points equal distribution. High-speed hydraulic-added value can increase the clamping speed.

Specification

Main technical parameters:

| Model | ZH50C | |

| Product size | Max. Product volume | 15~800ML |

| Max product height | 200mm | |

| Max product diameter | 100mm | |

| Injection system | Dia. of screw | 50mm |

| Screw L/D | 21 | |

| Max theoretical shot volume | 325cm3 | |

| Injection weight | 300g | |

| Max screw stroke | 210mm | |

| Max screw speed | 10-235rpm | |

| Heating capacity | 8KW | |

| No. of heating zone | 3 zone | |

| Clamping system | Injection clamping force | 500KN |

| Blow clamping force | 150KN | |

| Open stroke of mold platen | 120mm | |

| Lift height of rotary table | 60mm | |

| Max platen size of mold | 580*390mm(L×W) | |

| Min mold thickness | 240mm | |

| Mold heating power | 2.5Kw | |

| Stripping system | Stripping stroke | 210mm |

| Driving system | Motor power | 20Kw |

| Hydraulic working pressure | 14Mpa | |

| Other | Dry cycle | 3.2s |

| Compressed air pressure | 1.2 Mpa | |

| Compressed air discharge rate | >0.8 m3/min | |

| Cooling water pressure | 3.5 m3/H | |

| Total rated power with mold heating | 30kw | |

| Overall dimension(L×W×H) | 3800*1600*2230mm | |

| Machine weight Approx. | 7.5T | |

● Materials: suitable for majority kind of thermoplastic resins such as HDPE, LDPE, PP, PS, EVA and so on.

● Cavity number of one mouldcorresponding to product volume (for reference).

| Product volume(ml) | 8 | 15 | 20 | 40 | 60 | 80 | 100 |

| Cavity quantity | 9 | 8 | 7 | 5 | 5 | 4 | 4 |

-

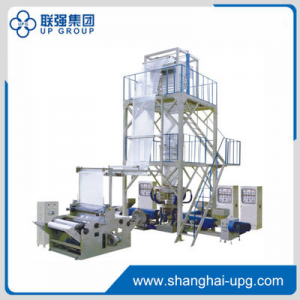

LQ A+B+C Three-layer Co-extrusion Film Blowing ...

-

LQYJHT80-SLll/8 Fully Automatic SL Blow Molding...

-

LQS PET Injection Moulding Machine Manufacturer

-

LQ V Series Standard Type Plastic Injection Mol...

-

LQ PE/PP/PVC Single-wall/Double-wall Corrugated...

-

LQ 3GS1200/1500 Three Layer Film Blowing Machin...