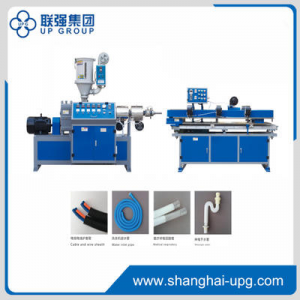

Product Description

● The mold head mechanism: the use of the split type of the head, not channeling material, more uniform, more uniform, more uniform, plating processing, not accumulating material, the material is more smooth.

● Plasticizing system: frequency conversion motor Hardened reducer with high quality nitride barrel screw, variable frequency speed control, energy efficient and stable yield.

● Electronic control system: the use of PLC man-machine interface, all parameters set, modify retrieval can be seen as the operation, the system runs stable,accurate positioning indeed.

● Application areas: food, medicine, petroleum, chemical, chemical, automotive, tool, toys and other industries.

● Can be equipped with automatic overflow device:supporting cutting device and pull the end device, automatic operation, save labor.

Specification

| Specification | SLD-75 | SLD-80 |

| Material | PE,PP,EVA,ABS,PS… | PE,PP,EVA,ABS,PS… |

| Max container capacity (L) | 10 | 15 |

| Number of die (Set) | 1,2,3,4,6 | 1,2,3,4,6 |

| Output(dry cycle) (pc/hr) | 600 | 600 |

| Machine Dimension(LxWxH) (M) | 4300*2400*2200 | 4600*2600*2200 |

| Total weight (Ton) | 7.5T | 8T |

| Clamping Unit |

||

| Clamping force (KN) | 65 | 68 |

| Platen opening stroke (MM) | 220-520 | 300-650 |

| Platen size(WxH) (MM) | 320*350 | 350*400 |

| Max mould size(WxH) (MM) | 400*350 | 450*400 |

| Mold thickness (MM) | 225-320 | 305-350 |

| Extruder unit |

||

| Screw diameter (MM) | 75 | 80 |

| Screw L/D ratio (L/D) | 25 | 25 |

| Melting capacity (KG/HR) | 80 | 120 |

| Number of heating zone (KW) | 20 | 24 |

| Extruder heating power (Zone) | 4 | 4 |

| Extruder driving power (KW) | 22 | 30 |

| Die head |

||

| Number of heating zone (Zone) | 2-5 | 2-5 |

| Power of die heating (KW) | 8 | 8 |

| Center distance of double die (MM) | 130 | 160 |

| Center distance of tri-die (MM) | 110 | 110 |

| Center distance of tetra-die (MM) | 100 | 100 |

| Center distance of six-die (MM) | 80 | 80 |

| Max die-pin diameter (MM) | 200 | 280 |

| Power |

||

| Max drive (KW) | 24 | 30 |

| Total power (KW) | 62 | 82 |

| Fan power for screw (KW) | 3.6 | 3.6 |

| Air pressure (Mpa) | 0.6 | 0.6 |

| Air consumption (m³/min) | 0.5 | 0.5 |

| Average energy consumption (KW) | 22 | 28 |