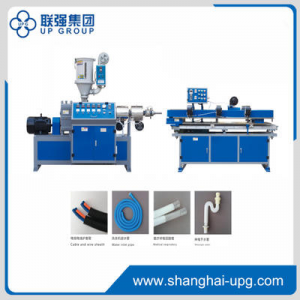

Product Description

Introduction:

Basic Machine

Carriage with linear motion system

1. Consisting of machine frame, extruder base frame and rear mounted control cabinet.

2. Horizontal mold carriage movement forward/backward on linear roller bearings.

3. Parallel opening/closing of blow mold, mold clamping area unobstructed by tie bars, fast build up of clamping force, variation in mold thickness possible.

4. Extrusion head lifting/lowering allowing continuous high parison extrusion head.

Hydraulic Unit

Integrated in the machine frame

1. Bosch-Rexroth servo variable speed pump and high pressure dosing pump, accumulator assisted, with energy saving function.

2. Oil cooling circuit equips with heat exchanger, temperature control and maximum oil temperature alarm.

3. Electrical monitoring of oil filter pollution and low oil level.

4. Hydraulic oil temperature controlled by PLC, ranging from 30oC~40oC.

5. The hydraulic unit is delivered without oil.

6. Tank capacity: 400 Liters.

7. Drive power:18.5kW Bosch-Rexroth servo pump &7.5kW VOITH dosing pump.

Specification

| Model | LQ10D-560 |

| Extruder | E60 |

| Extrusion Head | DS50-4F/1L-CD120/ 4-Fold/ 1-layer /Center distance:120mm |

| Article Description | 250ml 330ml HDPE botttle |

| Article Net Weight | 30g |

| Cycle Time | 22 seconds |

| Production Capability | 1300 pcs/hour |

| Clamping force | 100 kN (max 125 kN) |

| Width(max) | 550mm |

| Length(max) | 400mm |

| Thickness(min) | 2×120 mm |

| Mold weight(max) | 2×350 kg |

| Daylight(max) | 500mm |

| Daylingt(min) | 220mm |

| Claping stroke(max) | 280mm |

| Carriage shuttle stroke | 560mm |